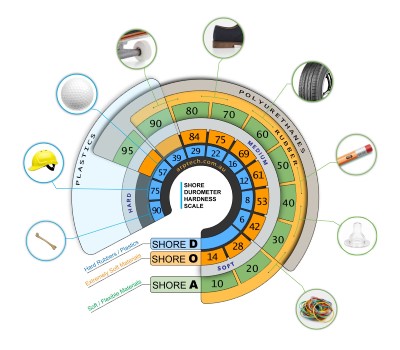

The Durometer or Shore durometer is typically used as a standard for measuring the hardness of non-metallic materials such as polymer, rubber, elastomer. The Shore hardness is measured with a device known as a Durometer and the determined hardness values are therefore referred to as Durometer hardness. There are several durometer scales, used for measuring hardness of materials with different properties.

Read MoreRapid prototyping is a quick, iterative method of creating prototypes of a product or component to test its design and functionality before mass production. This process involves using computer-aided design (CAD) software and advanced manufacturing technologies, such as 3D printing, to quickly produce a physical model of the product.

Read MoreThe role of rapid prototyping in the development of technological advancements in the medical industry is pivotal. It allows virtual simulation, experimentation, and realistic representation that have shaped our existing reality. The applications of rapid prototyping in the medical industry are enormous and invaluable on various fronts.

Read MoreGiven the part's geometry, CNC machining can be the most suitable and rapid method for creating metal and plastic prototypes. Usually, CNC machines produce a 3D object by removing excess material from the solid block, with the aid of cutting tools. The movement of these tools is precisely controlled by the series of cutter paths, generated directly from the 3d CAD model.

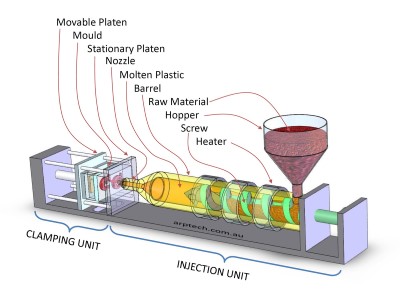

Read MoreInjection Moulding is a manufacturing process for producing parts by injecting molten material into a mould. Most injection moulding processes use thermoplastics because they can be melted and cooled down several times. The plastic injection moulding industry has come a long way since its inception, with the ability to produce large quantities of plastic products at a low price.

Read More3D metal printing is a 3D printing process that involves additively or layer-by-layer manufacturing 3D metal parts using a CAD (computer-aided design) model. This automated process is ideal for developing components and structures of prototypes that would otherwise prove too difficult or costly to make with traditional methods.

Read MoreThe fundamental motive in agriculture is to deliver adequate food, fibre, feed, and fuel for fulfilling the developing global demand. At the same time, rapid prototyping refers to present-day manufacturing technologies, which meet the unique requirements of the agriculture sector.

Read MoreRapid prototyping refers to quick manufacturing of a physical model, part, or assembly using 3D Computer-Aided Design (CAD). This approach has become instrumental for architectural engineers to check the validity and functionality before the product is produced or used on a large scale.

Read MoreUsing 3D-Printing in the mining industry, in particular, presents significant benefits to the entire industry. It makes the work of the mining sector straightforward and accessible, while increasing the efficiency of processes by cutting downtime on several tasks. In this blog, we'll be looking into a few advantages presented by using rapid prototyping in the mining industry.

Read More3D printing is often used in rapid packaging prototyping to evaluate packaging design. In the end, it allows you to improve and maintain your investment with the fastest turnarounds for elementary packaging prototypes and any required modifications. Consequently, it helps avoid unnecessary costs and delays while still maintaining your product integrity.

Read MoreBetween the design phase and the marketing phase of a particular product or an equipment, there are several steps that we should follow. One of the key milestones of the product manufacturing process is the selection of the most appropriate process for the production of that part. At the same time, you can identify that as one of the most important steps in the overall lifecycle of the product.

Read MoreWhen considering the CNC operations, they have been spread over a wide range, such as turning, milling, drilling, 3D printing, electric discharge machining, laser jet and water jet cutting. A detailed explanation of these mentioned types of CNC operations are presented in this article.

Read MoreBasically, aluminium anodising is an electrochemical process that can be used to develop an oxide coating of aluminium on the surface of a product. During this process, the surface layer of the aluminium product is converted into an aluminium oxide layer. Rather than providing considerably good protection against corrosion, the anodising process will improve the aesthetics of the product.

Read More3D printing, or additive manufacturing (AM), is one of the emerging technologies that are being applied for manufacturing components for a wide variety of applications. The low production cost, reduced time consumption, and high processing efficiency will increase the use of 3D printing technology in a variety of applications such as aerospace and defence, medical and dental, automotive, consumer goods, and so on. Let's take a quick look at 3D printing, also known as additive manufacturing technology. In this particular method, the manufacturing process is carried out by adding materials layer upon layer. 3D printing is a rapid prototyping technology that accelerates the ease of application.

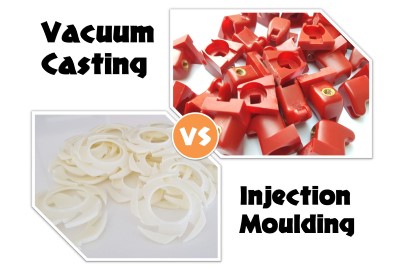

Read MoreFrom the concept to development stage of any kind of product cycle, there are a number of steps to follow, and one of the most important steps is the selection of product manufacturing process. A number of methods can be applied for carrying out this product manufacturing process, and in this article we are going to consider two very significant methods: vacuum casting and injection moulding. But, how can you select the most suitable method between these two for your application? Is there any specific criteria for that, or what is the benchmark for focusing only on one method over the other one?

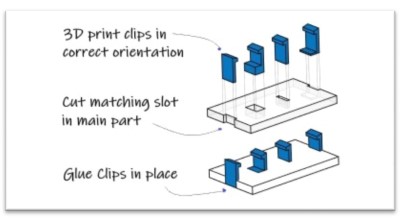

Read MoreLearn why 3D printed snap-fit clips break? How to avoid cracking clips and small features on 3D printed parts?

You'll discover, innovative ways to 3d-print thin wall and small features.

Rapid innovation and adoption of new technologies is driving major improvements in the performance of additive manufacturing (AM), also known as 3D printing. It is believed the Fourth industrial revolution has extensive dependency on fast-paced AM systems. We have created a comprehensive list of 3D printing and additive manufacturing related acronyms and terminology.

Read More