Snapshot of Aluminium

Aluminium Description

Aluminium is the most widely used non-ferrous metal. Aluminium is a soft, Durable, Lightweight, Ductile and Malleable metal with appearance ranging from Silvery to Dull Grey, depending on the surface roughness. Aluminium naturally generates a protective oxide coating and is highly corrosion resistant.

Advantages of Aluminium parts

Aluminium is an Excellent Heat and Electricity conductor, Excellent Corrosion resistance, Non-Magnetic and Non-Sparking. Aluminium is 100% recyclable without any loss of its natural qualities. Aluminium is a good reflector of visible Light and Heat.

Aluminium Uses

Large number of components for Automobiles, Aircraft, Trucks, Trains. Packaging application like beverage cans, foils. Construction industry, Wide range of household items, Consumer Electronics, Heat sinks for electronic appliances.

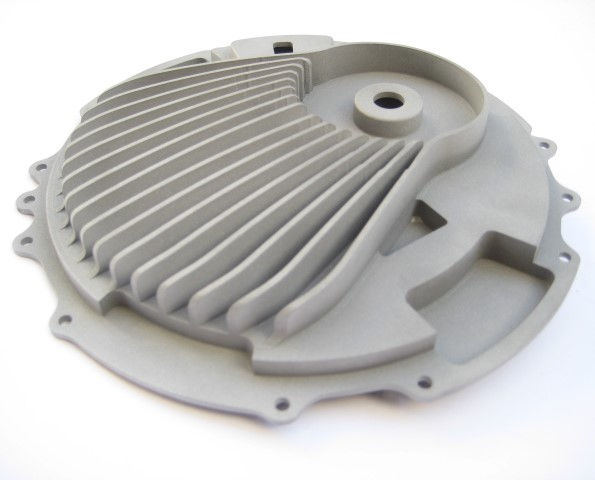

Finishing examples of Aluminium prototypes

Available Finishes

- Machine finish

- Polished finish

- Mirror polished finish

- Bead blast finish (to give matte texture)

- Anodising finish

- Painting finish

- Powder coating

Aluminium material Spec

| Property | Data |

|---|---|

Density

|

2.70 g/cm3 |

Tensile Strength (Mpa)

|

270 Mpa |

Modulus of Elasticity (GPa)

|

68.9 GPa |

Thermal Conductivity (k)

|

167 W/m-K |

Melting Point (℃)

|

585℃ |

Note: This Data is indicative only

|

|

Further considerations

Aluminium is a very lightweight metal, weighs about one third of steel with a density of 2.7 g/cm3. Aluminium forms a protective coating as soon as exposed to air. This thin layer builds up its resistance to corrosion which can be further improved by anodising.

Limitations

Unlike steels, Aluminium alloys have no well-defined fatigue limit, meaning that fatigue failure eventually occurs, under even very small cyclic loading. Subject to internal stresses following heating operations such as welding and casting due to low melting point.

Available grades of Aluminium?

- Aluminium 6061

- Aluminium 5083

- Aluminium 7075