Density (g/cm³)

For a homogeneous object, Density = Mass Divided By Volume. The higher the density, the tighter the particles are packed inside the substance. The Specific Gravity is the ratio of Density of the material to the Density of water at a specified temperature. It is common to use the density of water at 4°C as reference - at this point the density of water is at the highest i.e. 1 g/cm3. So Specific Gravity of less than “1” means that the material will float in water.

- ABS

g/cm³- PC

g/cm³- PP

g/cm³- ACETAL(POM)

g/cm³- ACRYLIC(PMMA)

g/cm³- NYLON

g/cm³- HDPE

g/cm³

Snapshot of Injection Moulding Process

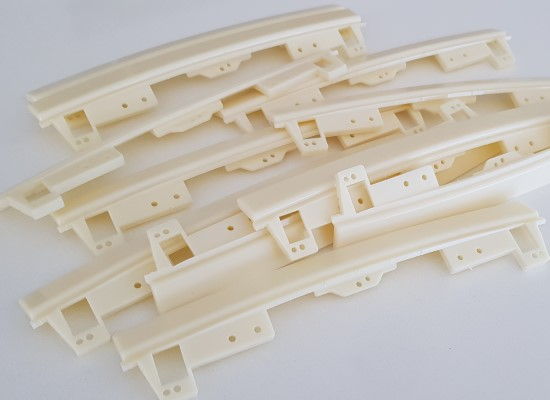

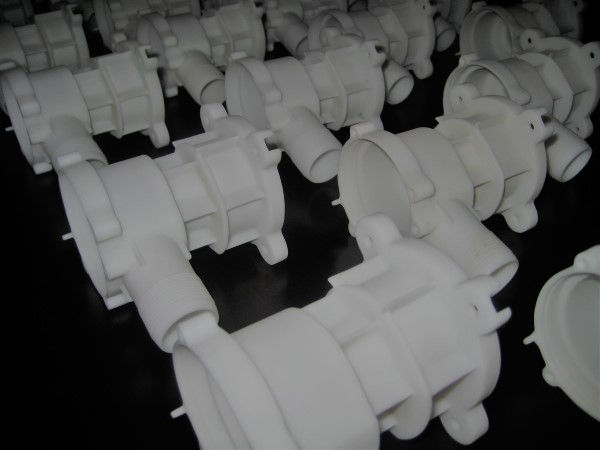

- Once Moulds are ready for production then injection moulding process itself is highly efficient and cost-effective.

- Injection moulding is ideal for high volume production of plastic moulded parts. High production output makes the moulding process cost-effective.

- Multiple types of plastics can be simultaneously used from a single mould.

- Consistent quality output achieved by repeatedly using the same mould for each component.

- Injection moulding can provide the desired finish even multiple finishes on the same part can be easily achieved.

- Plastic injection moulding is a sustainable process means waste can be easily recycled.

- Wide variety of moulding materials available ranging from opaque, transparent, translucent finish.

- Complex and intricate parts can easily be designed and manufactured by injection moulding process.

- Automotive Components: Dashboards, grilles, central console, cup holders, bumpers, head and tail light housings, reflectors made by the injection moulding process.

- Medical and Healthcare: Medical and surgical devices, orthopaedic devices, Hearing aids, inhalation masks, ventilator, Medication Trays.

- Electrical and Electronic components are commonly moulded with injection moulding process such as housings, Phones, enclosures, remote controls, computers, TV sets, printer housings, drone parts.

- Packaging: Food and Beverage packaging, Personal care and cosmetic packaging, Consumer packaged goods, Healthcare and Pharmaceutical packaging, Household and chemical Packaging

- Agriculture and Farming: Irrigation products, Pipes, Tractor parts, Farming machinery parts, sprinklers, water tanks.

- Building and Construction: Windows and doors, Hardware items, Fixtures, power-tool housings, Cladding panels, Pipe and Gutters, Plumbing parts, Bath and showers.

- Packaging: Food and Beverage packaging, Personal care and cosmetic packaging, Consumer packaged goods, Healthcare and Pharmaceutical packaging, Household and chemical Packaging

- Household, Leisure and Sports goods, Furniture, Home appliances, vacuum cleaner, Luggage items, Vending Machine components, Toys like Lego blocks, POP (Point of Purchase) display racks.

- Not economical for low volume production due to higher initial tooling cost.

- Plastic parts need to be designed by following set rules for injection moulding. Like complex undercuts, variable wall sections could be challenging.

- Lead time is higher due to initial tooling preparation.

How Injection Moulding process works

INTRODUCTION

Injection moulding is a manufacturing process used for producing parts by injecting molten resin into a mould. Most of the mass-produced plastic items are made by injection moulding process. Injection moulding is a very adaptable process used for moulding a wide range of thermoplastic materials and finishes, which makes it a popular option in numerous industries like automotive, aerospace, electrical, electronics, transportation, medical and healthcare.Firstly custom-made moulds are prepared, Tool steel is common material for preparing the moulds however aluminium or 3d-printed mould inserts can be used for short-run production. These moulds are mounted on an injection moulding machine and injected with a raw material which shapes the polymer into the desired form, creating identical copies of the same part.

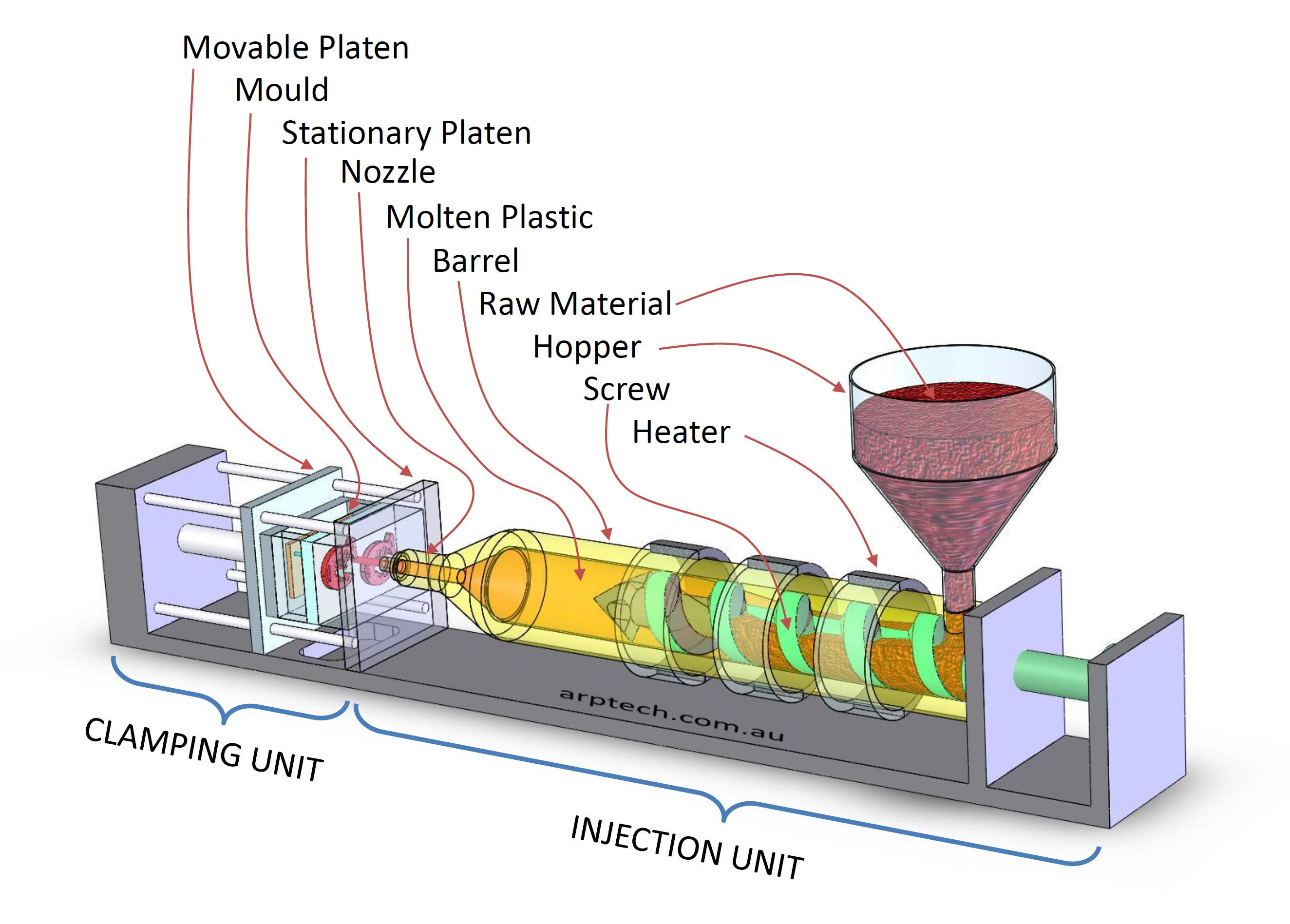

INJECTION MOULDING MACHINE OVERVIEW

PROCESS STEPS

The injection moulding process uses a special purpose machine consisting of three main parts: the injection unit, the mould and the clamping unit. Firstly plastic granules are loaded from a hopper into a spinning auger. These granules are passed through a heated chamber, called barrel where plastic is melted and injected into a mould with high pressure using plunger. The moving part of the mould is forced against the fixed part by a hydraulic ram with several tonnes of force. The plastic enters the mould cavity through a gate and runner system. After the cavity is filled, the mould is held closed during plastic injection and cooling cycle until plastic solidifies. At this time the auger screw and barrel retracts to its original position to get ready for the next cycle. Once the moulded part cools down completely, the mould is forced to open by the hydraulic ram and the moulded item is ejected out for further processing. The next injection moulding cycle repeats as soon as the mould closes and the plastic is injected into the mould cavity.

Common Thermoplastics used in Injection Moulding

Usage: Toys (Lego bricks), electronic housings, pipes, boat and automotive components.

Usage: Automotive Lighting, Hair dryer, power tool parts, medical equipment like dialysis machine components.

Usage: PP is heavily used in packaging industry. Automotive parts, Home appliances, Electronic components, Construction items, Kitchen utensils and equipments, Hardware items, living hinges due to flexibility and good fatigue resistance.

Usage: Automotive components like cooling, fuel intake systems, Electrical and electronics components, bushes, gears, bearings, textile machinery, building materials, vacuum cleaners, food processing machinery, printing machines, medical equipment, footwear, sports equipment.

Usage: Automotive fuel systems, valves, electric tooth brush, water filters, sprinklers, pumps, water meters, garden tools, impellers, irrigation and plumbing applications, bushes, gears, bearings, fasteners, food processing machinery, medical equipment, lawn and garden machinery, fuel tanks, washing machine parts, refrigerator components, electrical relays, switches, watch components.

Usage: Automotive industry like instrument panels, dashboard components and pillar trims. Electronic equipments, Laptop, desktop computers, fax machine, copiers, printers, plotters and monitors. Telecommunication industry like mobile phone housing.