What are the user expectations from 3D Printed parts?

Imagine you spent hours and hours to 3D Print an electronic assembly housing or enclosure with snap features. Your excitement is on high level to do the fitment testing, but as soon as you fit the parts together, ouch! Clip features break into pieces. All your excitement goes into the drain, not to mention the time, money, and resources wasted. It’s very difficult to salvage broken clips, no matter how strong glue you use. But don’t despair; it’s not user’s fault, rather limitation of 3d printing process to make clips and snap features effectively.

Can 3D printed objects with small features crack easily?

Yes, in fact, it’s a very common issue with 3d printed parts to crack on narrow sections. 3D printing is a generic term and commonly associated with additive manufacturing (AM) processes encompasses many technologies including FDM, SLA, SLS. All types of 3D printers, associated with various printing technologies, have their own pros and cons. However, layering has great impact on FDM based 3D printed parts.

Does part orientation affect the strength of 3D printed parts?

The short answer, yes, part orientation is the first and foremost consideration before you plan to 3d print the part. The mechanical performance of 3D printed parts is highly dependent upon the orientation of the part relative to the build plane. Specifically, for extrusion-based printing systems, such as FDM printers.

Anisotropic or Isotropic:

This indicates that aligning the part at different orientations around the build platform can greatly influence the end results of the finished products. FDM printed parts can be classified as anisotropic.

On the other hand, SLA and SLS printed parts can be classified as isotropic in mechanical properties. This indicates that aligning the part at different orientations will result in more or less similar properties along different directions We’ll go through several orientation layouts of parts and discuss pros and cons. Before discussing these options, let’s discuss why thin wall features or clips break. Read it through to the end, surely you’ll find out some tips.

Why Clips and Small Features break on 3D printed parts?

To elaborate the concept, let’s compare two brick and mortar walls. Both masonry walls constructed out of same material and height, however one wall is single brick width and second wall is continuous perimeter wall. You can easily figure out that single width wall will break easily due to limited surface bonding between the brick-layers. On the other side, long-stretched wall has interconnectivity from one brick to another, hence increases surface bonding to enhance the strength of the wall. The same brick-wall principle applies to the FDM printed parts, as the bond between successive layers can be a lot weaker than in the printed plane (x-y plane). In a nutshell, smaller the cross-sectional bonding area, easier to crack.

In a real world of product development, we can’t change the product features to suit our printer capability and incapability. Therefore, we have to find out innovative solutions to 3D print small features effectively and efficiently.

Let’s delve into practical solutions to print clip and small features with illustrative examples:

Lay down the part on side face (works for narrow parts)

Quick point to make; this blog is not about how to design snap clip features for 3d printing, that we'll cover in another blog, rather let's concentrate on how to 3d print existing clips without altering the design features.

Avoid printing clips in vertical Z-direction, as the shear forces while flexing will cause snapping parts between layers, reducing the part’s strength significantly. As the above image depicts, 3D printed part clips perform the best when printing layer lines follow the flex direction of the clips (while printing, the side face of the clip is facing towards the baseplate)

When part size is large and desired printing orientation is not feasible?

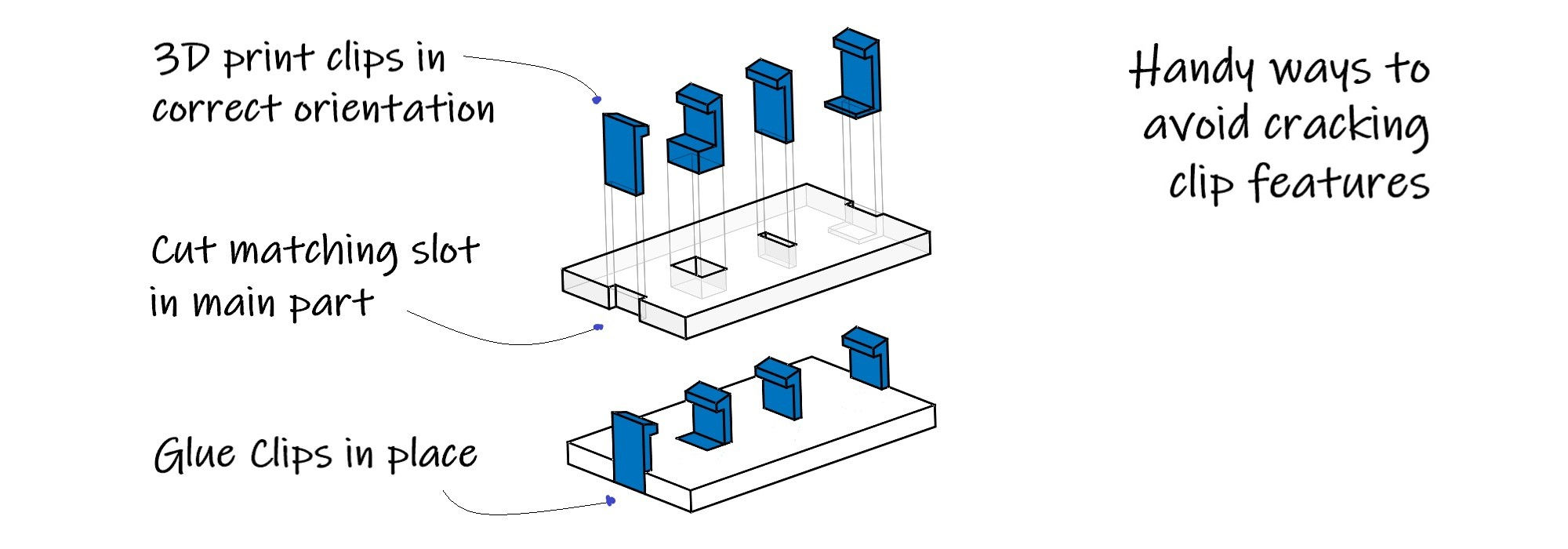

From the above example, it's clear that by correct orientation of part, we can achieve the best results for cantilever clips. But sometimes it's not possible to orient the part in desirable orientation due to other implications. In such cases, the best approach is to isolate the clip areas by making a modular section of clip and glue them in place.

As per the above image, there are many ways to cut and glue those clips. The whole concept is to print the clips in right orientation and achieve the full functionality. The same rule applies to other small features such as bosses, pegs, ribs which can be printed separately.

Clips or small features reinforced with foreign material.

This is an unconventional way of printing clips, here at ArpTech lab, we've successfully developed a way to reinforce the clips. How this method works: A narrow rectangular slot is cut through the clip section. A thin layer of plastic or metal sheet is inserted into the slot and glued in place.

The above example is a novel way of reinforcing clips. A thin slice of plastic or metal sheet sandwiched between the clip can change the stiffness of the clip, yet performing at its best capacity.

Small features strength enhanced with pins

Above example of reinforcement rule can be applied to the other thin and narrow features. For example, small pegs or standalone bosses can be strengthened with steel or plastic pins.

Insider tip to strengthen small bosses: design with small guide hole from back of boss, straighten the paper clip, lightly heat-up and insert from back. That will become the integral part of the protruded boss.

Conclusion

If you are not satisfied with the performance of your 3D printed parts, don't despair! Here at ArpTech we have a wide variety of materials available which are suitable for clips or snap features. We can effectively CNC machine out of engineering grade of plastics such as ABS, Nylon, PP, Acetal(POM), PC or 3D print using SLS technology. Experience the benefits of the functional parts made by established manufacturing technologies. For further consideration, please refer to CNC Machining or SLS 3D-Printing service page.