Snapshot of Stainless Steel

Stainless Steel Description

Stainless Steel is a generic term for a family of corrosion resistant alloy steels containing at least 10.5% of Chromium. All stainless steels have a high resistance to corrosion. The ease with which it can be steam-cleaned and sterilised, and the absence of the need for surface coatings have prompted the use of stainless steel in kitchens and food processing plants.

Advantages of Stainless Steel parts

Resistance to corrosion and staining, low maintenance, and familiar lustre make stainless steel an ideal material for many applications where both the strength of steel and corrosion resistance are required. All stainless steels have a high resistance to corrosion.

Stainless Steel Uses

The clean-ability of stainless steel makes it the first choice in hospitals, kitchens, food and pharmaceutical processing facilities, cookware, cutlery, surgical instruments, washing machine drums, catering equipment, brewing, distilling, food processing, street furniture, auto parts, fasteners.

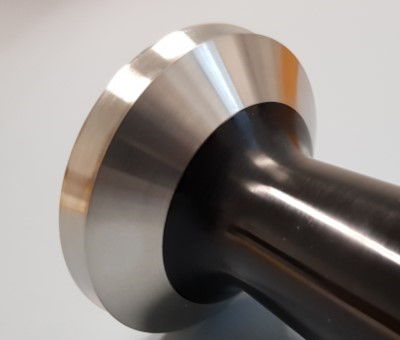

Finishing examples of Stainless Steel prototypes

Available Finishes

- Machine finish

- Polished finish

- Mirror polished finish

- Bead blast finish (to give satin texture)

Stainless Steel material Spec

| Property | Data |

|---|---|

Density

|

8.0 g/cm3 |

Tensile Strength (Mpa)

|

515 Mpa |

Modulus of Elasticity (GPa)

|

193 GPa |

Thermal Conductivity (k)

|

14 W/m-K |

Melting Point (℃)

|

1400℃ |

Note: This Data is indicative only

|

|

Further considerations

Stainless steel is usually divided into 5 types: Ferritic, Austenitic, Duplex, Martensitics, Precipitation hardening (PH). We use Austenitic type of stainless steel with available grades SS304 and SS316 with having good general corrosion resistance, good cryogenic toughness.

Limitations

High material cost, higher machining cost, difficult to weld, high cost of polishing and finishing.

Available grades of Stainless Steel?

- SS304

- SS316