Snapshot of Mild Steel

Mild Steel Description

Mild Steel is the most common form of steel widely used in various industries. Mild steel is a form of low-carbon steel comparatively having low amount of carbon contents ranging from 0.05 to 0.25%, making it malleable and ductile. It becomes malleable when heated, and so can be forged.

Advantages of Mild Steel parts

Mild Steel has high tensile and impact strength. Good ductility and weldability. Mild Steel is hard, yet malleable, even when cold. Mild steel can be machined and formed into different shapes easily due to its inherent flexibility.

Mild Steel Uses

Mild Steel is extensively used as structural steel in manufacturing and construction industry due to easy processing and relatively economical than other steels. Machinery, Ship-building and automobile manufacturing, Hardware items, Fence, Fasteners. Pipelines and Poles manufacturing due to ease of welding and stability in harsh environment.

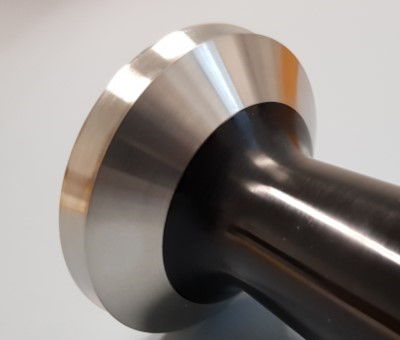

Finishing examples of Mild Steel prototypes

Available Finishes

- Machine finish

- Polished finish

- Painting

- Bead blast finish (to give satin texture)

Mild Steel material Spec

| Property | Data |

|---|---|

Density

|

8.0 g/cm3 |

Tensile Strength (Mpa)

|

515 Mpa |

Modulus of Elasticity (GPa)

|

193 GPa |

Thermal Conductivity (k)

|

14 W/m-K |

Melting Point (℃)

|

1400℃ |

Note: This Data is indicative only

|

|

Further considerations

Mild steel has ferromagnetic properties, which make it ideal for manufacture of electrical devices and motors.

Limitations

Very weak resistance to corrosion makes mild steel to easily corrode. Mild steel is not suitable for heat treatment, unable to show any significant change in structure due to lower carbon content.