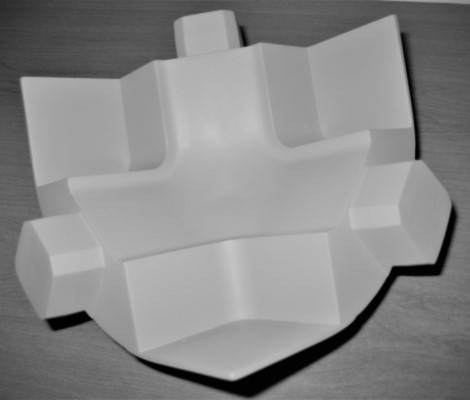

Snapshot of PVC Plastic

PVC plastic Description

Polyvinyl chloride (PVC) is a solid plastic material made from vinyl chloride, it can be made softer and more flexible by the addition of plasticizers. PVC is one of the most commonly used thermoplastic material used in building and construction.

Advantages of PVC parts

Excellent strength and toughness, good abrasion resistance and toughness, good mechanical strength and chemical resistance, good tensile strength.

PVC plastic Uses

Rigid form of PVC is widely used in construction, medical, and automotive industry like plumbing pipes, windows and doors frames. It is also used in making hoses, medical devices, cable coatings and automotive parts. Packaging industry has wider applications like bottles, thermoformed boxes and blister packs

Finishing examples of PVC prototypes

Available Finishes

- Machine finish

- Polished finish

- Painted finish

PVC material Spec

| Property | Data |

|---|---|

Density

|

1.39 g/cm3 |

Water Absorption-24 Hours (%)

|

0.25 % |

Tensile Strength (Mpa)

|

35 Mpa |

Tensile Modulus (GPa)

|

2.9 GPa |

Flexural Strength (MPa)

|

75 Mpa |

Vicat Softening Temp (℃)

|

80℃ |

Heat Deflection Temp - 1.8MPa (℃)

|

70℃ |

Coefficient of Friction

|

0.40 |

Note: This Data is indicative only

|

|

Further considerations

PVC can be easily bonded to various other plastics by using different methods. PVC is chemically resistant to acids, salts, bases, fats, and alcohols. PVC is a polymer with good insulation properties.

Limitations

PVC is degraded by UV light and intolerance to high temperatures causes poor heat stability. PVC emits toxic fumes when melted.