Density (g/cm³)

For a homogeneous object, Density = Mass Divided By Volume. The higher the density, the tighter the particles are packed inside the substance. The Specific Gravity is the ratio of Density of the material to the Density of water at a specified temperature. It is common to use the density of water at 4°C as reference - at this point the density of water is at the highest i.e. 1 g/cm3. So Specific Gravity of less than “1” means that the material will float in water.

- ABS

g/cm³- PC

g/cm³- PP

g/cm³- ACETAL(POM)

g/cm³- ACRYLIC(PMMA)

g/cm³- NYLON

g/cm³- HDPE

g/cm³

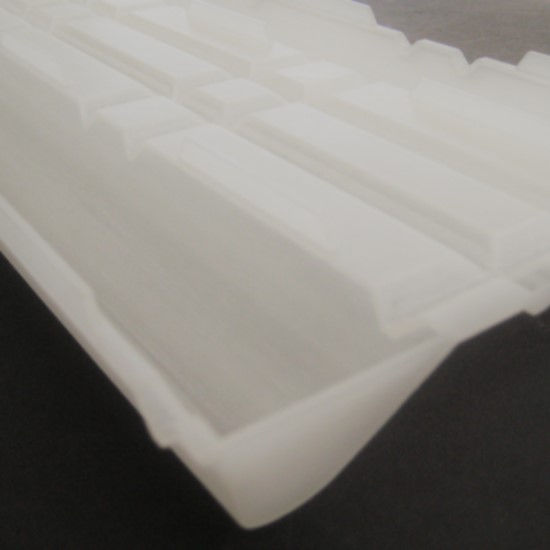

Snapshot of Polypropylene Plastic

PP plastic Description

PolyPropylene is semi-opaque thermoplastic widely used in a variety of applications. Polypropylene has good resistance to fatigue. PP offers a combination of outstanding physical, chemical, mechanical, thermal and electrical properties.

Advantages of PP parts

Excellent resistance to fatigue. Lightweight with good combination of toughness and flexibility. Resists most alkaline and acids. Low moisture absorption and non-toxic. Good impact resistance. Retains stiffness and flex. Food contact acceptable. Excellent resistance to organic solvents, degreasing agents. High stiffness.

PP plastic Uses

Appliance housings, Food Packaging, Medical and Laboratory applications because it can withstand the heat in an autoclave, Pump Components, Casings with Living Hinges, Automotive parts, Food Containers, Industrial Applications, Loudspeaker drive units, Household Goods.

Finishing examples of PP prototypes

Available Finishes

- Machine finish

- Polished finish

PP material Spec

| Property | Data |

|---|---|

Density

|

0.99 g/cm3 |

Water Absorption-24 Hours (%)

|

0.02 % |

Tensile Strength (Mpa)

|

33 Mpa |

Tensile Modulus (GPa)

|

1.20 GPa |

Flexural Strength (MPa)

|

45 Mpa |

Vicat Softening Temp (℃)

|

80℃ |

Heat Deflection Temp - 1.8MPa (℃)

|

45℃ |

Coefficient of Friction

|

0.30 |

Note: This Data is indicative only

|

|

Further considerations

Polypropylene is one of the lightest plastics available. Easy to machine and provide smooth finish. Since PP is resistant to fatigue, makes it suitable for most of plastic living hinged parts, such as flip-top bottle caps.

Limitations

Hard to glue. Degraded by UV radiation, attacked by chlorinated solvents and aromatics. Large and thin wall sectioned parts are prone to deformation or warpage after machining.