Density (g/cm³)

For a homogeneous object, Density = Mass Divided By Volume. The higher the density, the tighter the particles are packed inside the substance. The Specific Gravity is the ratio of Density of the material to the Density of water at a specified temperature. It is common to use the density of water at 4°C as reference - at this point the density of water is at the highest i.e. 1 g/cm3. So Specific Gravity of less than “1” means that the material will float in water.

- ABS

g/cm³- PC

g/cm³- PP

g/cm³- ACETAL(POM)

g/cm³- ACRYLIC(PMMA)

g/cm³- NYLON

g/cm³- HDPE

g/cm³

Snapshot of Polycarbonate (PC)

PC plastic Description

Unfilled PolyCarbonate (PC) is a tough and durable, transparent engineering thermoplastic notable for its high impact resistance, temperature resistance and optical properties.

Advantages of PC parts

High impact resistance, Good Dimensional Stability, Excellent strength retention at elevated temperatures, Low coefficient of thermal expansion, Good Dimensional Stability. Good electrical insulator and having Heat resistant and Flame retardant properties.

PC plastic Uses

Automotive headlamp Lenses and Safety Shields, Medical/Healthcare apparatus, Automotive Applications, Construction Industry, Sporting Goods, Appliances, Casing and housings, Electrical/Electronic components, Connectors, Compact Discs, Telecommunication Hardware.

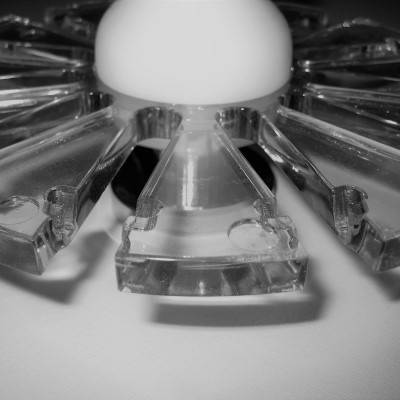

Finishing examples of PC prototypes

Available Finishes

- Machine finish

- Transparent finish (like lens)

- Translucent bead-blast finish (like foggy lamp shade)

- Painted or Grey primered

PC material Spec

| Property | Data |

|---|---|

Density

|

1.20 g/cm3 |

Water Absorption-24 Hours (%)

|

0.15 % |

Tensile Strength (Mpa)

|

64 Mpa |

Tensile Modulus (GPa)

|

2.20 GPa |

Flexural Strength (MPa)

|

90 Mpa |

Vicat Softening Temp (℃)

|

136℃ |

Heat Deflection Temp - 1.8MPa (℃)

|

131℃ |

Coefficient of Friction

|

0.38 |

Note: This Data is indicative only

|

|

Further considerations

Typically, parts have translucent look after machining, but transparency can be achieved by highly polishing. It's strength, durability, impact resistance and transparency make it an ideal material for certain structural applications. Large and complex parts with undercuts can be made in sections and glued.

Limitations

Subject to cracking due to stress, moderate resistance to Chemicals, Low scratch-resistance.