Vacuum Casting for Low-volume producion of Hard or Soft Parts

What is Vacuum Casting

VC (Vacuum Casting) is typically used for casting prototypes out of polyurethane resins. The process starts with creation of a master model, using various RP techniques. This master model is used to build a silicon rubber mould. Now these mould cavities are used to cast a large variety of polyurethane or epoxy materials available.

How Vacuum Casting Process works:

VC (Vacuum Casting) also known as Urethane casting, is a widely used process in the Rapid Prototyping industry, typically used for making 20 to 40 pieces of functional prototypes out of the broad range of polyurethane resins available. The process starts with creation of an accurate and highly finished master model which can be created using various RP techniques e.g. SLA, FDM, SLS, CNC or existing part. This model is carefully placed in a mould box and liquid silicon rubber is poured over the master. After curing the silicon, the mould is cut as per split line established and the master model is removed, leaving an accurately formed cavities. Now these mould cavities are used to cast a large variety of polyurethane or epoxy materials available. This allows fast production of high quality parts in a short lead time. A broad range of polyurethanes with various physical properties enable the production of prototypes to more closely mimic the functional properties of engineering thermoplastics.

Advantages of Vacuum Casting

- Silicone rubber tooling is a low-cost solution for producing small quantity of functional parts in a short lead time.

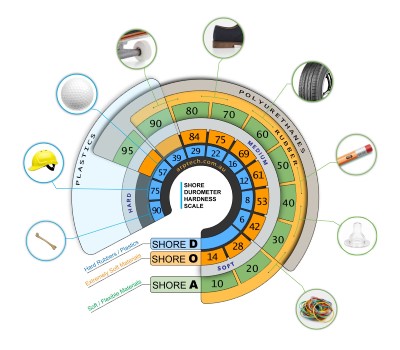

- Large variety of urethane materials available to mimic the injection moulded materials ranging from soft rubber grades to hard plastics.

- High quality surface finish including large range of colours and textured finish available.

- Special features like Insert moulding, threaded inserts can be easily moulded inside the castings.

- Silicon moulding has distinctive advantage over hard tooling that it allows limited undercuts or negative draft angle features.

Limitations of Vacuum Casting

- Vacuum cast parts are not identical to an injection moulded parts, because the conditions and method of manufacture are different.

- Single mould can make only 15 to 20 parts and most of the time need to make a new master model for the next mould.

- Very thin wall sections are not recommended and chances of cracking or warping.

General applications of Vacuum Cast parts

- Excellent and low-cost solution for pre-production release of parts for Marketing, Advertisement.

- Conceptual models for effectively evaluating, optimising and communicating your design.

- Parts for Functional testing or Exhibition display purpose.

- Packaging design or promotional product photography.

- Deliver Low volume production in a short lead time similar quality to injection moulded parts.

Use Vacuum Casting for:

- For producing small quantity of functional parts in a short lead time.

- Mimic the injection moulded materials ranging from soft rubber grades to hard plastics.

- High quality surface finish including large range of colours and textured finish.

- Low-cost solution for pre-production release of parts for marketing, advertisement, functional testing.

- Insert moulding, threaded inserts can be easily moulded inside the castings.